Customer precision CNC yatunganije ibice bya Titanium hamwe no kurasa

Ingorane muriCNCgutunganya no gushushanya ibice bya Titanium

Imashini ya CNCya titanium alloys itanga urutonde rwihariye rwibibazo bitewe nimiterere yibikoresho. Titanium izwiho kuba ifite imbaraga nyinshi-ku bipimo, kurwanya ruswa, hamwe na biocompatibilité, bigatuma ihitamo gukundwa cyane mu kirere, mu buvuzi, no mu modoka. Ariko, ibyo biranga bimwe nabyo bigora inzira yo gutunganya.

Gutunganya Ibibazo

1. Kwambara ibikoresho:Amavuta ya Titanium azwiho gukurura, guterakwambara ibikoresho byihuse. Imbaraga nyinshi za Titanium bivuze ko ibikoresho byo gutema bigomba gukorwa mubikoresho bigezweho nka karbide cyangwa ububumbyi kugirango uhangane n'imihangayiko irimo. Ndetse hamwe nibikoresho, ubuzima bwibikoresho burashobora kuba bugufi cyane ugereranije no gutunganya ibyuma byoroshye.

2. Ubushyuhe:Titanium ifite ubushyuhe buke bwumuriro, bivuze ko ubushyuhe butangwa mugihe cyo gutunganya butagabanuka vuba. Ibi bitera ihindagurika ryumuriro wakazi nigikoresho cyo gukata, bikavamo ubuso bubi burangiye hamwe nuburyo budahwitse. Ingamba nziza zo gukonjesha, nko gukoresha sisitemu yo gukonjesha umuvuduko ukabije, ni ngombwa kugirango iki kibazo gikemuke.

3. Gukora Chip:Uburyo imitwe ya titanium ikora mugihe cyo kuyitunganya irashobora kandi gutera ibibazo. Bitandukanye nicyuma cyoroshye gitanga chipi zihoraho, titanium mubisanzwe itanga chip ngufi, nziza zishobora guhuzwa nigikoresho cyangwa igihangano, bikarushaho kugorana.

4. Gukora ibipimo:Guhitamo umuvuduko ukwiye, igipimo cyibiryo hamwe nubujyakuzimu bwo gukata ni ngombwa. Ibipimo bikarishye cyane birashobora kuganisha ku kunanirwa kw'ibikoresho, mugihe igenamigambi ryitondewe cyane rishobora kuvamo gukora neza kandi igihe cyo kongera umusaruro. Kubona impirimbanyi nziza bisaba uburambe bunini no kugerageza.

5. Gufata Igikorwa:Titanium ifite modulus nkeya ya elastique, bivuze ko izahinduka mukibazo, bigatuma igihangano gikora ikibazo. Ibikoresho byihariye hamwe nuburyo bwo gufatira hamwe birasabwa kenshi kugirango ibice bigume bihamye mugihe cyo gutunganya, bishobora kongera ibintu bigoye hamwe nigiciro mubikorwa.

Ikibazo

NyumaCNCgutunganya biruzuye, anodizing titanium alloy irusheho kugora inzira yo gukora.Anodizingni amashanyarazi yubaka imbaraga zirwanya ruswa kandi itanga iherezo ryiza. Ariko, anodizing titanium izana hamwe ningorane zayo.

1. Gutegura Ubuso:Ubuso bwa titanium bugomba gutegurwa neza mbere yo gukora anodizing. Ibihumanya byose, nk'amavuta cyangwa ibisigazwa byo gutunganya, birashobora gutera gufatana nabi kurwego rwa anodize. Ibi akenshi bisaba ubundi buryo bwo gukora isuku, nko gusukura ultrasonic cyangwa guterwa imiti, byongera igihe nigiciro.

2. Kugenzura uburyo bukoreshwa:Inzira ya anodizing ya titanium yunvikana kubintu bitandukanye, harimo voltage, ubushyuhe hamwe na electrolyte. Kugera kumurongo umwe udasanzwe bisaba kugenzura neza ibyo bihinduka. Guhindagurika birashobora kuvamo ibara nubunini budahuye, ibyo bikaba bitemewe murwego rwo hejuru rusobanutse.

3. Guhuza amabara:Anodize titanium irashobora gutanga amabara atandukanye bitewe nubunini bwurwego rwa anodize. Ariko, kugera kumabara ahoraho mubice byinshi birashobora kugorana bitewe nuburyo butandukanye kurangiza nubunini. Uku kudahuza kurashobora kuba ikibazo kubisabwa aho uburinganire bwuburanga ari ngombwa.

4. Ubuvuzi nyuma ya anodize:Nyuma ya anodizing, hashobora gusabwa ubundi buryo bwo kuvura kugirango imikorere yimikorere idahwitse. Ibi bishobora kubamo uburyo bwo gufunga, bishobora kurushaho kugora akazi no kongera igihe cyo gukora.

Mu gusoza

Imashini ya CNC hamwe na anodizing ya titanium alloys ni ibintu bigoye bisaba ubumenyi bwihariye, ibikoresho nikoranabuhanga. Imashini zijyanye no gukora imashini, nko kwambara ibikoresho, kubyara ubushyuhe no gukora chip, hamwe nuburyo bugoye bwa anodizing, bishimangira ko hakenewe igenamigambi ryitondewe no kuyishyira mubikorwa. Nkuko ibyifuzo bya titanium ikora cyane bikomeje kwiyongera mu nganda, gutsinda izo ngorane ni ingenzi kubabikora bagamije kubahiriza ubuziranenge n’imikorere.

HY Metals ninzobere mu gutunganya CNC hamwe nubushakashatsi burenze imyaka 14, twakoze ibice byinshi bya Titanium bifite ubuziranenge kandi bwiza.

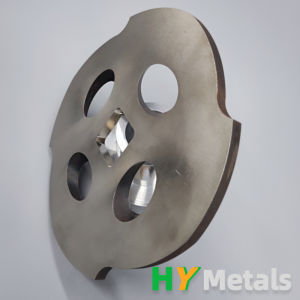

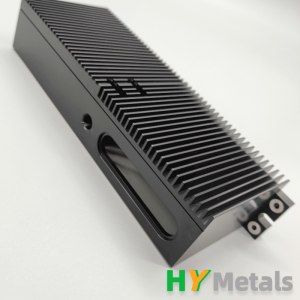

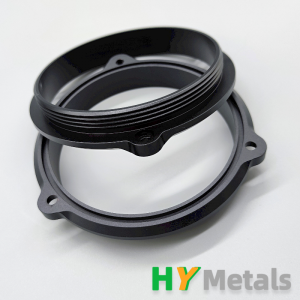

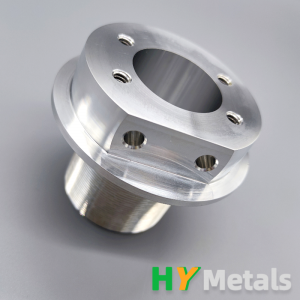

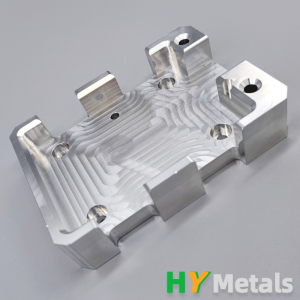

Hano hari bamwe bashya baCNC yakoze ibice bya Titaniumyakozwe na HY Metals.

HY Ibyumagutangaguhagarara rimweserivisi zikora ibicuruzwa harimourupapuro rwo guhimba naImashini ya CNC, Imyaka 14 uburambe kandiIbikoresho 8 byuzuye.

CyizaUbwizakugenzura,ngufiimpinduka,bikomeyeitumanaho.

Ohereza RFQ yawe hamweibishushanyo birambuyeUyu munsi. Tuzagusubiramo ASAP.

WeChat:na09260838

Bwira:+86 15815874097

Imeri:susanx@hymetalproducts.com