Flatness ni kwihanganira geometrike ikomeye mugutunganya, cyane cyane kumpapuro zimpapuro na CNC yo gutunganya. Yerekeza ku bihe aho ingingo zose ziri hejuru zingana nindege yerekanwe.

Kugera kuburinganire ni ngombwa kubwimpamvu zikurikira:

1. Imikorere ikora:Ibice byinshi bigomba guhuza neza neza. Niba ibice bitaringaniye, birashobora gutera kudahuza kandi bikagira ingaruka kumikorere rusange yinteko.

2. Gukwirakwiza imizigo:Ubuso buringaniye butanga no kugabura imitwaro. Ubuso butaringaniye bushobora gutera guhangayika bishobora gutera kunanirwa hakiri kare.

3. Ubwiza bw'ubwiza:Mu nganda aho isura ari ngombwa, nk'imodoka n’ibikoresho bya elegitoroniki, uburinganire bufasha kuzamura ibicuruzwa bigaragara.

4. Gukora neza Inteko:Ibice bitaringaniye birashobora kugora gahunda yo guterana, bigatuma ibiciro byakazi byiyongera.

5. Icyifuzo cyo gukomeza gutunganya:Kuringaniza akenshi nibisabwa kugirango ibikorwa bizakurikiraho nko gucukura cyangwa gusya, aho ubuso bukenewe kugirango haboneke ibisubizo nyabyo.

Komeza uburinganire mugihe cyo gutunganya

Kugera no kubungabunga uburinganire mugihe cyo gutunganya bisaba gutegura neza no kubishyira mubikorwa. Dore ingamba zimwe:

1. Guhitamo Ibikoresho:Hitamo ibikoresho bitari byoroshye kurigata cyangwa guhindura ibintu mugihe cyo gutunganya. Ibyuma bifite coefficient zo hasi zo kwagura ubushyuhe muri rusange birakunzwe.

2. Gukosora Ibikoresho:Koresha ibikoresho bikwiye kugirango ufate neza urupapuro rwakazi mugihe cyo gutunganya. Ibi bigabanya kugenda no kunyeganyega bishobora gutera intambara.

3. Kugenzura ibipimo byo gutunganya:Hindura uburyo bwo guca umuvuduko, kugaburira n'uburebure bwo gukata. Ubushuhe bukabije butangwa mugihe cyo gutunganya burashobora gutera kwaguka kwinshi no gukomera.

4. Imashini zikurikirana:Niba bishoboka, ibice byimashini mubyiciro. Ibi bituma ibikoresho bivanwaho muburyo bugenzurwa, bikagabanya ibyago byo guhinduka.

5. Kuvura nyuma yo gutunganywa:Reba uburyo bwo kugabanya imihangayiko nka nyuma yo gutunganya annealing cyangwa ibisanzwe kugirango ukureho imihangayiko yimbere ishobora gutera intambara.

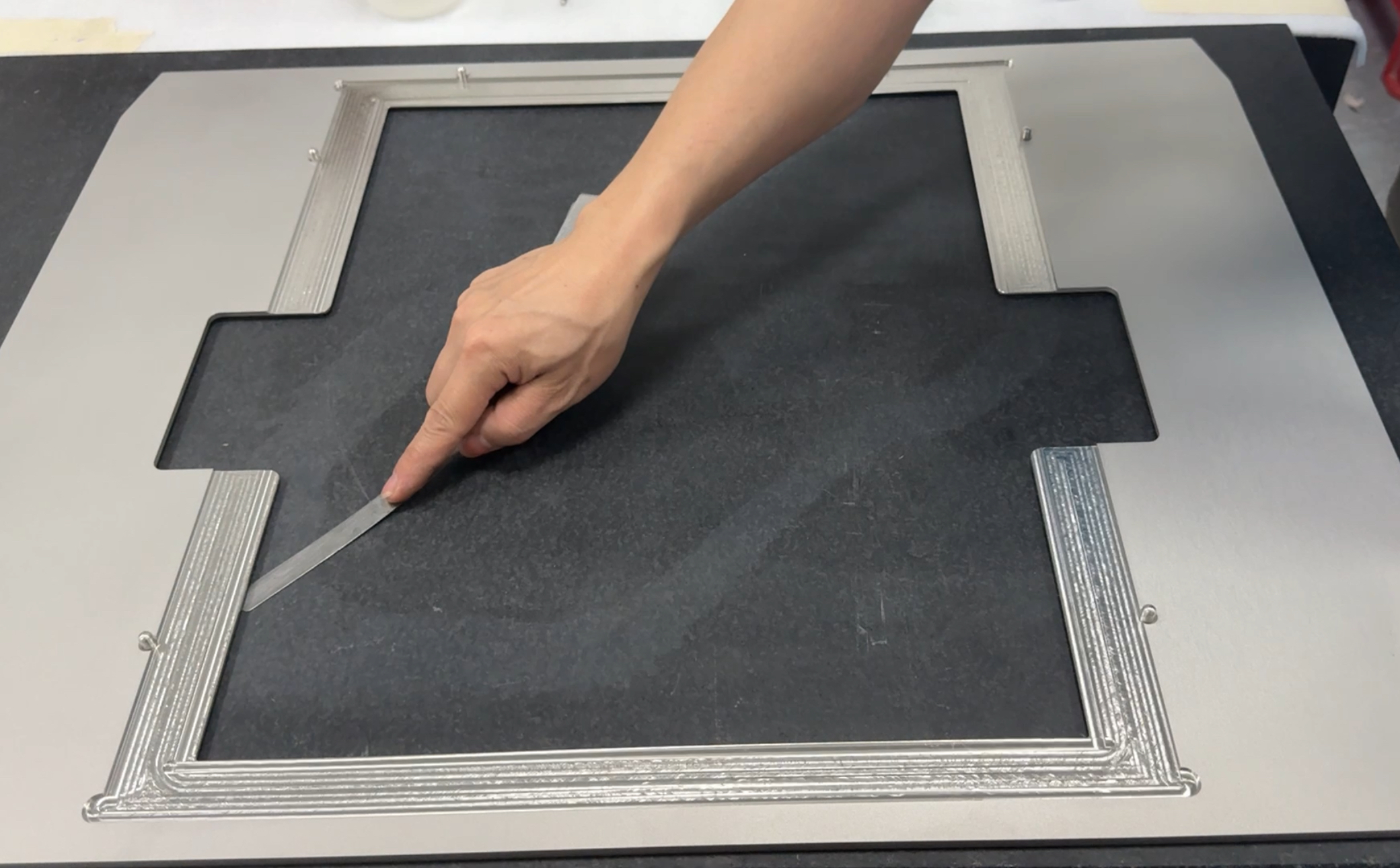

6. Gukoresha Flat Reference Surface:Buri gihe ugenzure kandi uhindure ibikoresho byimashini kugirango umenye neza ko bikora hejuru.

Reba neza

Kugira ngo ibyoibicekuzuza ibisobanuro birambuye, tekiniki zikwiye zo kugenzura zigomba gukoreshwa:

1. Kugenzura Amashusho:Igenzura ryoroshye rishobora rimwe na rimwe kwerekana ibibazo bigaragara neza, nkibyuho munsi yigice cyangwa urumuri runyura.

2. Uburyo bw'abategetsi:Shira umutegetsi utomoye hejuru kandi ukoreshe igipimo cyo gupima gupima icyuho cyose. Ubu buryo ni bwiza cyane bwo kugenzura byihuse.

3. Ikimenyetso cyo guhamagara:Ikimenyetso cyerekana kirashobora gukoreshwa mugupima uburinganire bwuburinganire bwubuso bwose. Ubu buryo butanga ibipimo nyabyo.

4. Guhuza imashini ipima (CMM):Kubisobanuro bihanitse cyane, CMM irashobora gukoreshwa mugupima uburinganire bwubuso ifata amanota menshi no kubara gutandukana kwindege.

5. Uburyo bwiza bw'indege:Ibi bikubiyemo gukoresha indege ya optique hamwe numucyo umwe kugirango ugenzure neza. Uburyo bwo kwivanga bushobora kwerekana gutandukana.

6. Gusikana Laser:Ikoranabuhanga rya laser yogusuzuma ritanga ikarita yubuso burambuye, itanga isesengura ryuzuye ryuburinganire.

Mu gusoza

Kureshya ni ikintu cyingenzi cyo gutunganya, bigira ingaruka kumikorere, ubwiza no guteranya neza. Mugusobanukirwa akamaro kayo no gushyira mubikorwa ingamba zo kubungabunga no kugenzura uburinganire,HET METALS irashobora kwemeza umusaruro wibintu byiza byujuje ubuziranenge. Kugenzura buri gihe no kubahiriza uburyo bwiza bwo gutunganya bizamura imikorere yibicuruzwa no guhaza abakiriya.

HY Ibyumagutangaguhagarara rimwe serivisi zikora ibicuruzwa harimo urupapuro rwo guhimbanaImashini ya CNC,Uburambe bwimyaka 14naIbikoresho 8 byuzuye.

CyizaUbwizakugenzura, ngufiimpinduka,bikomeyeitumanaho.

Ohereza ibyaweRFQ hamweibishushanyo birambuye Uyu munsi. Tuzagusubiramo ASAP.

WeChat:na09260838

Bwira:+86 15815874097

Imeri:susanx@hymetalproducts.com

Igihe cyo kohereza: Ukwakira-10-2024